Eva Rubber is gaining remarkable popularity in various industries. This versatile material boasts impressive durability, flexibility, and resistance to extreme temperatures. A recent report by the International Rubber Study Group highlights that Eva Rubber usage in consumer products has increased by over 30% in the last five years. The applications range from footwear to automotive components.

Dr. Emily Carter, a renowned expert in polymer materials, notes, "Eva Rubber’s unique properties make it essential in everyday products." This statement encapsulates why it is favored among manufacturers. Its lightweight nature and enhanced cushioning capabilities greatly improve user experience in sports equipment and protective gear.

However, not everything about Eva Rubber is perfect. The environmental impact of its production raises questions. While it offers numerous benefits, the sustainability of its sourcing process demands attention. As we explore the top benefits of Eva Rubber, these considerations remind us to balance innovation with responsibility.

Eva rubber, known for its lightweight and flexible nature, has become a go-to material in product design. Its versatility allows manufacturers to create a wide array of items, from footwear to protective gear. Recent studies indicate that the market for EVA rubber is expected to reach $7.6 billion by 2027. This growth highlights its burgeoning role in various industries.

In product design, EVA rubber is favored for its cushioning and shock absorption properties. Footwear manufacturers leverage these qualities to enhance comfort. For instance, EVA foam is frequently used in insoles to provide extra support. Notably, it also boasts superior resistance to UV radiation and water, making it perfect for outdoor gear. Tips: Always evaluate the environmental impact of the materials used in your designs.

Despite its advantages, there are challenges. Some may question the long-term durability of EVA rubber under extreme conditions. Additionally, it can be more expensive than other materials. As designers, it’s vital to weigh the costs versus the benefits. Tips: Prototype and test extensively to ensure product longevity. This proactive approach can reveal potential weaknesses.

| Benefit | Description | Example Applications |

|---|---|---|

| Lightweight | Eva rubber is extremely lightweight, making it easy to handle and transport. | Footwear, sports gear |

| Durability | Offers high resistance to wear and tear, prolonging the life of products. | Yoga mats, insoles |

| Flexibility | Eva rubber can be easily shaped without compromising its strength. | Molded parts, toy designs |

| Water Resistant | Excellent resistance to moisture, making it suitable for various environments. | Floating devices, outdoor equipment |

| Shock Absorption | Provides cushioning and impact resistance, enhancing comfort. | Sports footwear, protective gear |

| Chemical Resistance | Resistant to many chemicals, ensuring product integrity over time. | Industrial applications, sealants |

| Thermal Insulation | Effective thermal insulator, suitable for temperature-sensitive products. | Coolers, insulation panels |

| Non-Toxic | Safe for consumer use, containing no harmful substances. | Children's toys, kitchenware |

| Customization | Can be easily dyed or printed on, allowing for creative designs. | Branded products, color-coded items |

| Cost-Effective | Affordable material choice for manufacturers without sacrificing performance. | Consumer goods, packaging materials |

Eva rubber is gaining traction due to its exceptional durability and impact resistance. This material is lightweight, yet remarkably strong. It withstands wear and tear, making it ideal for various applications. Whether used in footwear or padding, Eva rubber combines comfort and resilience.

In everyday products, Eva rubber can absorb shock effectively. This feature is crucial for items like mats or protective gear. For instance, yoga mats made from Eva provide excellent cushioning. They keep users stable, even during intense sessions. Additionally, their water-resistant nature extends product lifespan.

However, not all Eva rubber products are created equal. Some may degrade faster when exposed to harsh conditions. Users should pay attention to quality and specifications. It’s important to consider these factors when choosing Eva rubber items. An informed decision can enhance durability and overall experience.

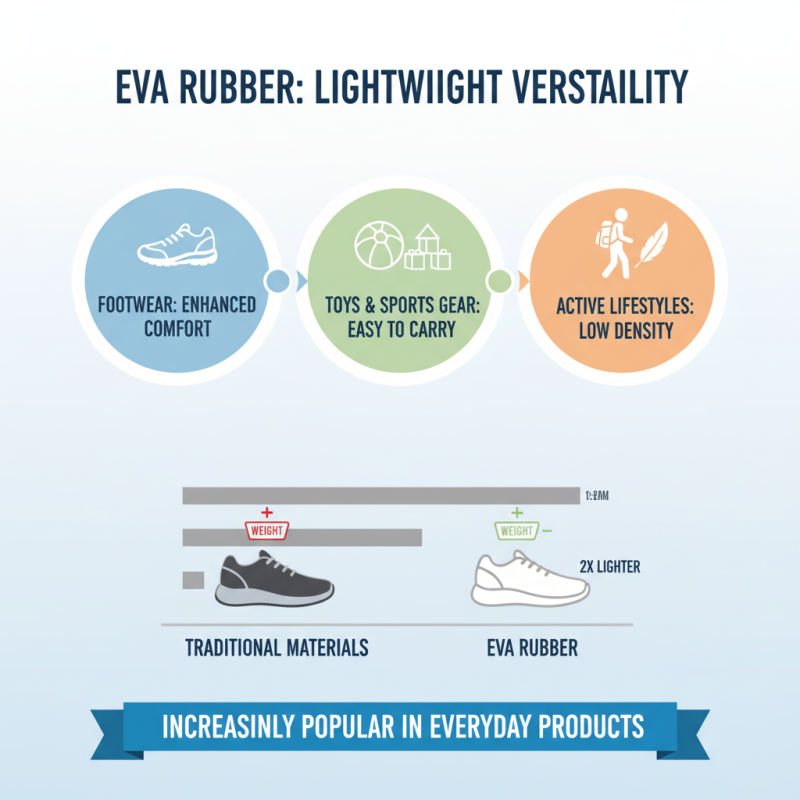

Eva rubber is increasingly popular in everyday products due to its lightweight properties. This versatile material is often found in footwear, toys, and sports equipment. Its low density makes it easy to carry and manage. For instance, shoes made from Eva rubber are lighter than those made from traditional materials. This feature enhances comfort, especially for active lifestyles.

In addition to being lightweight, Eva rubber offers a soft, cushioned feel. This is noticeable in gym mats or padding in furniture. However, there are challenges to consider. Not all Eva rubber products are equally durable. Over time, some may lose their shape or performance. It’s important to evaluate products based on their specific use case. While Eva rubber generally provides excellent benefits, it's crucial to balance expectations with reality. Not every application will yield the same benefits as others.

Eva rubber is becoming essential in sustainable product design. Its lightweight and durable nature makes it an excellent choice for various applications. A study by the Environmental Protection Agency highlights that the use of eco-friendly materials can reduce carbon footprints by up to 30%. Eva rubber, derived from ethylene and vinyl acetate, is generally considered non-toxic. Many manufacturers are replacing traditional plastics with Eva rubber to address environmental concerns.

The manufacturing process of Eva rubber emits fewer pollutants compared to conventional materials. In fact, reports indicate that producing Eva rubber can result in a 20% lower greenhouse gas emission rate. Moreover, Eva is often used in products like footwear, insulation, and toys, helping brands lower their environmental impact. While it is a step forward, not all Eva rubber is recyclable. This limitation urges manufacturers to innovate further.

As consumers become more eco-conscious, the demand for sustainable materials is rising. Yet, the industry faces challenges, such as sourcing raw materials sustainably. A recent survey indicated that over 40% of companies struggle with eco-friendly sourcing. This indicates a need for better supply chain transparency in the production of Eva rubber.

Eva rubber stands out in various manufacturing processes due to its cost-effectiveness. According to a report by Smithers Pira, the EVA market is projected to grow significantly, reaching a value of $6 billion by 2025. This growth is partly due to EVA’s low production costs and high versatility. Manufacturers can utilize EVA in several applications, from footwear to insulation materials.

One key advantage is its ease of processing. EVA rubber can be molded and extruded efficiently, leading to reduced labor costs. Industries report a 20% decrease in production time when using EVA compared to traditional materials. This efficiency allows businesses to allocate resources more effectively, ensuring better profit margins.

Tips for manufacturers: consider bulk purchasing. Many suppliers offer discounts for larger orders, reducing costs further. Experiment with blends of EVA to find the most cost-effective solution for your specific needs. Keep an eye on industry trends, as advancements in technology may offer new, cheaper methods for EVA production. Balancing quality with cost is vital; cheap materials can sometimes lead to increased returns when not managed properly.