In today’s electronic landscape, the protection of sensitive components has become paramount, especially as the global electronics market is projected to reach $1 trillion by 2025, as per a recent report from Statista. With static electricity posing a significant threat to electronic devices, the adoption of ESD shielding bags has surged, highlighting their vital role in the supply chain. According to the Electrostatic Discharge Association (ESDA), millions of dollars in revenue are lost each year due to ESD-related damage, making the selection of appropriate ESD shielding bags pivotal for electronics manufacturers and consumers alike. This guide aims to provide insights into choosing the right ESD shielding bags, ensuring optimal protection against electrostatic discharge (ESD) while enhancing the longevity and reliability of electronic devices.

Electrostatic discharge (ESD) can have a devastating impact on electronic devices, leading to performance issues or complete failure. According to a report by the ESD Association, nearly 30% of all device failures can be attributed to ESD events. This statistic highlights the critical need for effective ESD protection in both manufacturing and handling processes. Any electronic component, from semiconductors to circuit boards, can be compromised by even a minor static shock.

Understanding ESD is essential for anyone involved in electronics, as it can manifest in various forms, such as contact discharge and air discharge. The protective use of ESD shielding bags plays a crucial role in mitigating these risks. These specialized bags are designed to prevent electrostatic fields from affecting sensitive components, ensuring their integrity throughout the supply chain. A study by IPC reveals that implementing proper ESD control measures, including the use of shielding bags, can reduce ESD-related failures by as much as 98%. Being informed about ESD and its potential consequences will help businesses choose the right protective materials and maintain the reliability of their electronic products.

When selecting ESD shielding bags for electronics, understanding the different types and their applications is crucial. There are primarily two types of ESD bags: metal-in and metal-out. Metal-in bags feature a layer of metal sandwiched between two layers of polymer, which provides excellent shielding against electrostatic discharge. These bags are ideal for sensitive components like integrated circuits and semiconductors. According to a report by the ESD Association, nearly 30% of semiconductor failure is attributed to ESD, emphasizing the importance of using appropriate shielding solutions.

On the other hand, metal-out bags have the conductive layer on the outside, which is effective for both protecting contents from ESD and preventing external interference. They are often used for bulk storage and shipping of sensitive items. A study by IPC indicated that nearly 75% of companies dealing with electronic products rely on some form of ESD packaging, highlighting its critical role in maintaining product integrity during handling and transport. Selecting the right type of ESD shielding bag based on the specific application can significantly mitigate risk and ensure the longevity of electronic components.

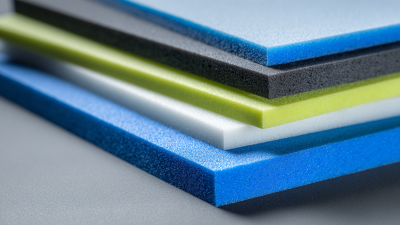

When selecting the right ESD shielding bags for your electronics, it’s essential to focus on several key features that ensure optimal protection. One of the most critical aspects is the material of the bag. Look for bags made from high-quality materials such as polyethylene or metallized films that provide a barrier against electrostatic discharge. These materials not only shield sensitive components from electrostatic buildup but also offer durability to withstand handling during transport and storage.

Another important feature is the bag's construction. Opt for bags that are heat-sealed or have strong seams to prevent contamination and ensure a tight closure. Additionally, consider the bag's static decay rates, which indicate how quickly a bag can dissipate static charges. A bag with a rapid static decay rate can effectively protect electronic parts during the packing and unpacking processes. Lastly, ensure that the bags are clearly labeled with static warning symbols to enhance safety during use and handling, providing an extra layer of protection for delicate electronic components.

Proper storage and handling of ESD shielding bags are crucial for maintaining the integrity of sensitive electronic components. First, it’s essential to select a clean, dry environment for storage.

ESD bags should be kept away from direct sunlight and extreme temperatures, as these factors can degrade the shielding properties of the bags over time. Ideally, they should be stored in a climate-controlled area with stable temperature and humidity levels. Additionally, ensure that the bags are not subject to mechanical stress or pressure from heavy objects during storage to prevent damage.

When it comes to handling ESD shielding bags, it's important to wear appropriate grounding equipment, such as wrist straps or ESD footwear, to minimize the risk of electrostatic discharge. Always handle the bags with clean, dry hands or use gloves to prevent contamination. When placing items inside the bags, make sure they are clean and free from dust or debris, as these contaminants can compromise the bag's effectiveness. Lastly, ensure that the bags are correctly sealed to provide maximum protection against ESD while in transit or storage.

When selecting ESD protection solutions, it's crucial to avoid common pitfalls that can compromise the integrity of sensitive electronics. One of the notable mistakes is neglecting the specifications of ESD shielding bags. According to industry reports, properly rated shielding bags must meet specific performance criteria, including surface resistivity and electrostatic discharge protection levels. For instance, bags should ideally have a surface resistivity between 103 and 1011 ohms to provide effective shielding against ESD events.

Another common oversight is underestimating the implications of micro-contamination and stiction in ESD-sensitive environments. Recent studies highlight that these issues can lead to significant **MEMS (Micro-Electro-Mechanical Systems)** failures. Stiction, which occurs when two surfaces stick together due to static charges, can cause severe operational disruptions. Understanding these failure mechanisms is vital; ensuring that components are appropriately protected not only prevents damage from electrostatic discharge but also mitigates risks from micro-contaminants and mechanical shocks. Prioritizing comprehensive ESD protection strategies can safeguard electronics, especially in critical applications such as automotive Ethernet where enhanced voltage ESD protection is necessary.