In the rapidly evolving landscape of electronics manufacturing, the protection of sensitive components from electrostatic discharge (ESD) remains a critical concern. According to industry reports, approximately 30% of all electronic failures are attributed to ESD-related damage, underscoring the need for effective protective measures.

ESD Shielding Bags have emerged as a vital solution for safeguarding these delicate devices from the harmful effects of static electricity during storage and transportation. These bags, designed with a combination of conductive and dissipative materials, provide a controlled environment that significantly reduces the risk of ESD damage.

As the electronics market continues to grow, projected to reach $1.2 trillion by 2025, the implementation of robust packaging solutions like ESD Shielding Bags will be crucial to ensuring product reliability and longevity, making it essential for manufacturers and consumers alike to understand their proper usage and benefits.

As the electronics market continues to grow, projected to reach $1.2 trillion by 2025, the implementation of robust packaging solutions like ESD Shielding Bags will be crucial to ensuring product reliability and longevity, making it essential for manufacturers and consumers alike to understand their proper usage and benefits.

Electrostatic discharge (ESD) shielding bags are essential for protecting sensitive electronic components from damage caused by static electricity. Understanding the different types of ESD shielding bags and their unique features is crucial for ensuring maximum protection. Broadly, these bags can be categorized into static shielding bags, conductive bags, and anti-static bags, each serving specific purposes based on the sensitivity of the electronics they safeguard.

Static shielding bags are typically made from a multi-layered construction that incorporates a conductive layer sandwiched between insulating layers. This design prevents electrostatic fields from entering the bag while also dissipating any charges that may accumulate on its surface. Conductive bags, on the other hand, allow for the passage of electrical current, making them ideal for items that require grounding to prevent buildup of static electricity. Anti-static bags, often utilized for less sensitive components, can protect against static charge through their specially formulated materials that reduce the likelihood of static electricity generation. Each type of bag offers distinct protective features, highlighting the importance of selecting the right one for effective ESD protection in electronics handling and storage.

When selecting the right ESD shielding bag for your sensitive electronics, it is crucial to consider both the material and thickness of the bag. ESD shielding bags are typically made from conductive materials that prevent static electricity from damaging electronic components.

Thicker bags provide increased protection, but it is essential to balance thickness with flexibility to ensure ease of use. Look for bags that conform to industry standards, such as ASTM D257 and MIL-B-81705, to guarantee effective protection.

When selecting the right ESD shielding bag for your sensitive electronics, it is crucial to consider both the material and thickness of the bag. ESD shielding bags are typically made from conductive materials that prevent static electricity from damaging electronic components.

Thicker bags provide increased protection, but it is essential to balance thickness with flexibility to ensure ease of use. Look for bags that conform to industry standards, such as ASTM D257 and MIL-B-81705, to guarantee effective protection.

Additionally, consider the size and type of the electronic components you need to protect. ESD bags come in various sizes, and choosing one that fits your equipment snugly will minimize movement and potential damage.

You can also opt for static-dissipative zipper bags for easy access or resealable options that offer ongoing protection. Ultimately, thorough research and an understanding of your specific electronics' requirements will help you select the ideal ESD shielding bag, ensuring your devices remain safe from the harmful effects of electrostatic discharge.

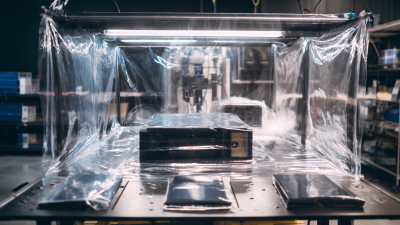

When packing sensitive electronics, the proper techniques for using ESD shielding bags are crucial to ensure optimal protection. First, ensure that the workspace is grounded to prevent static build-up that could harm electronic components. Always handle electronic devices by their edges to minimize potential contact with sensitive areas. Before placing the device into the ESD bag, check for any debris or moisture that could compromise the shielding effectiveness.

Tips: When sealing the ESD bag, use an airtight method to prevent any contaminants from entering. It's also beneficial to remove excess air from the bag, as this can further reduce the risk of static electricity buildup. Label the bags clearly with the contents and handling instructions, which will aid in the safe transportation and storage of the electronics. Ensure that multiple layers of protection, such as antistatic bubble wrap, are used when necessary, especially during shipping.

Lastly, always store ESD bags in a cool, dry environment. Avoid exposing them to direct sunlight or extreme temperatures; this can weaken the materials and reduce their efficacy. Following these practices will greatly enhance the protection of your sensitive electronics while in transit or storage.

When it comes to storing sensitive electronics, especially semiconductors, employing anti-static packaging solutions like ESD shielding bags is essential. These bags not only protect against electrostatic discharge but also provide an environment that minimizes the risk of dust and moisture damage. Proper storage is key to ensuring the longevity and functionality of your electronic components.

Tips: Always ensure that ESD bags are correctly sealed to maintain their protective qualities. Avoid folding or creasing bags, as this can compromise their effectiveness. Additionally, keep these bags in a temperature-controlled environment, as extreme temperatures can diminish their shielding capabilities over time.

When handling ESD shielding bags, it's important to practice safe handling techniques. Use grounded work surfaces and wear anti-static wrist straps when packaging or unpacking sensitive devices. This will significantly reduce the risk of electrostatic discharge, ensuring that your components remain intact and fully operational. Remember, proactive measures in packaging can save you from costly damages down the line.

When using ESD (Electrostatic Discharge) shielding bags, common issues can arise that affect their effectiveness in protecting sensitive electronics. One prevalent problem is improper sealing of the bags. According to a report by the ESD Association, improperly sealed bags can compromise their shielding effectiveness by up to 90%, ultimately leading to potential damage of electronic components. It is vital to ensure that the bags are sealed correctly to prevent any electrostatic discharge from penetrating the bag.

Another common issue involves the selection of the right type of ESD shielding bag. ESD bags come in several materials, such as metallized film or conductive plastic, and each provides different levels of protection. A study conducted by IPC—Association Connecting Electronics Industries indicated that choosing the wrong ESD bag can lead to failures in protecting sensitive devices, with nearly 30% of manufacturers experiencing heightened failure rates due to incorrect bag material. Careful consideration of the specific requirements of the electronic components being protected is essential to avoid costly mistakes.