The packaging industry is undergoing significant transformation, and one of the driving forces behind this change is the emergence of Eva Board Sheets. These innovative materials have been reported to enhance durability by an impressive 30%, as highlighted in the recent market analysis by Smithers Pira, which projects that the sustainable packaging market will reach $300 billion by 2024.

With increasing demand for eco-friendly solutions and higher performance standards, Eva Board Sheets stand out for their ability to combine lightweight design with substantial impact resistance. Additionally, a study by MarketsandMarkets indicates that the global packaging market is expected to grow at a CAGR of 3.5% through the next five years, solidifying the necessity for durable and sustainable materials.

As businesses seek to reduce waste and improve efficiency, Eva Board Sheets are not just a trend but a vital component in redefining the standards of modern packaging solutions.

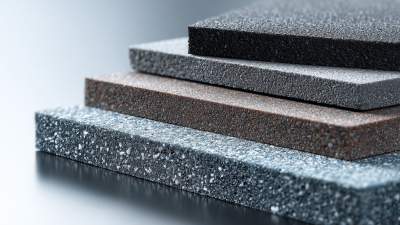

Eva board sheets are gaining traction in the packaging industry due to their remarkable durability and sustainability, standing out against traditional packaging materials. Unlike conventional options that often succumb to wear and tear, Eva board sheets boast a 30% increase in durability, making them optimal for protecting goods during transport. This advantage is increasingly crucial in a market projected to experience significant growth; for instance, the aluminum silicon carbide packaging market is expected to rise from $67 million in 2022 to $129 million by 2030, highlighting the need for robust materials.

Eva board sheets are gaining traction in the packaging industry due to their remarkable durability and sustainability, standing out against traditional packaging materials. Unlike conventional options that often succumb to wear and tear, Eva board sheets boast a 30% increase in durability, making them optimal for protecting goods during transport. This advantage is increasingly crucial in a market projected to experience significant growth; for instance, the aluminum silicon carbide packaging market is expected to rise from $67 million in 2022 to $129 million by 2030, highlighting the need for robust materials.

Moreover, as sustainability becomes a critical focus in packaging, Eva board sheets present a modern alternative that utilizes less plastic and reduces waste. Data from recent reports indicate a pressing shift towards environmentally friendly options, with the biodegradable plastics market anticipated to expand rapidly; for example, the soluble packaging market is projected to grow from $3.78 billion in 2024 to $5.65 billion by 2032. This trend aligns with evolving consumer preferences, where sustainable solutions are increasingly favored, positioning Eva board sheets favorably in the competitive landscape of the packaging industry.

The recent innovation of Eva Board Sheets is setting new standards in the packaging industry, primarily due to their remarkable 30% increased durability. One key factor contributing to this enhanced durability is the advanced polymer composition used in Eva boards. This material is designed to withstand extreme environmental conditions, making it highly resilient against wear and tear. The unique molecular structure of Eva not only provides flexibility but also effectively absorbs impacts, protecting the contents from damage during transit.

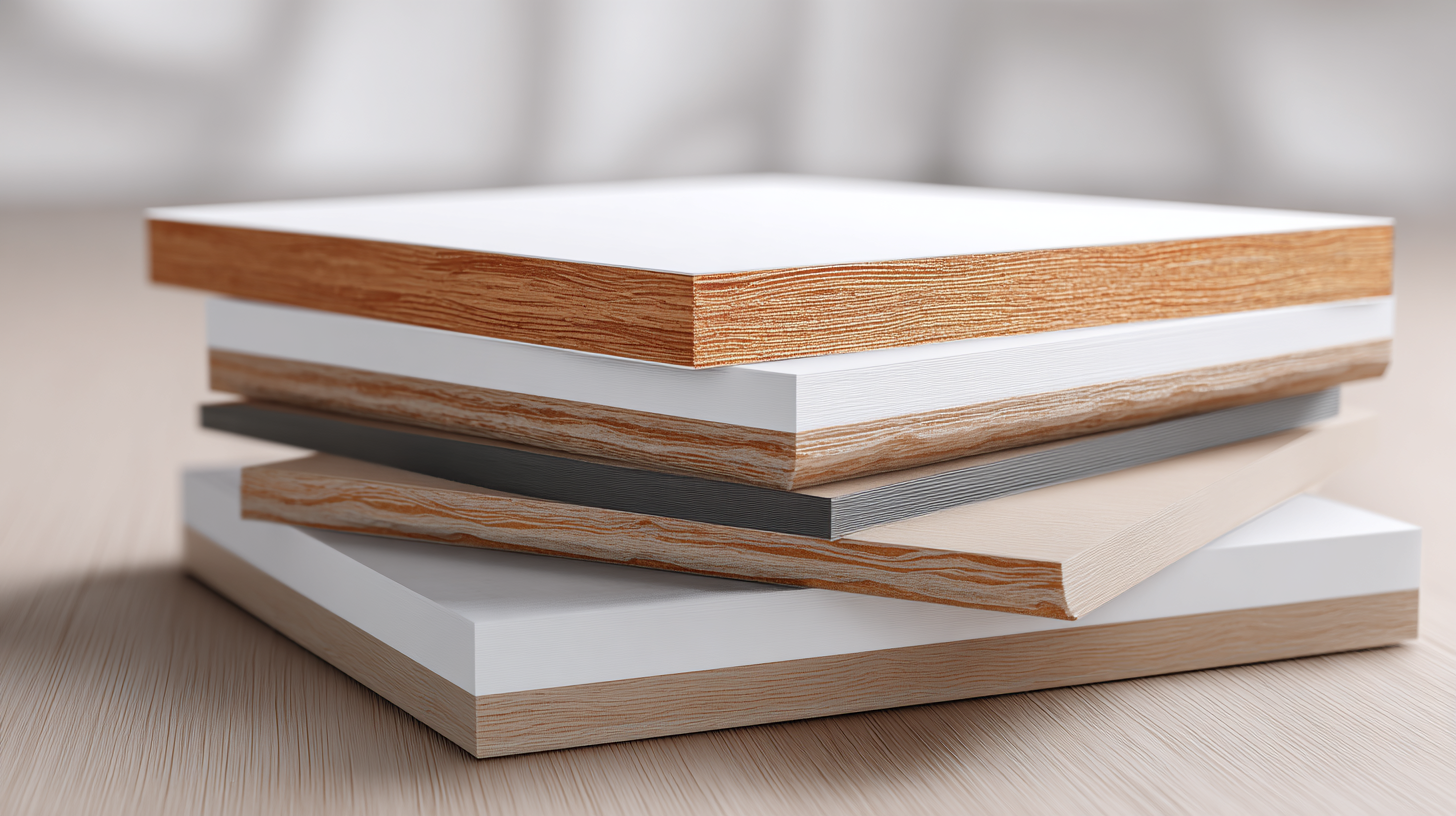

Another important factor is the manufacturing process. Eva Board Sheets are produced using cutting-edge technology that ensures consistent quality and seamless bonding. This meticulous attention to detail minimizes the likelihood of weak spots that can lead to failure under stress. The result is a packaging solution that not only lasts longer but also maintains its integrity over time.

Tips for Choosing Eva Board Sheets: When selecting Eva Board Sheets for your packaging needs, consider their thickness and specific applications. Thicker sheets typically offer better protection for heavier items. Additionally, evaluate the environmental certifications of the product, as sustainable options are becoming increasingly favored in the industry. Finally, always request samples to assess the durability firsthand before making a bulk purchase.

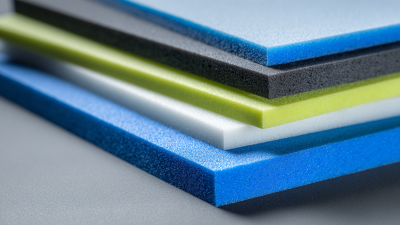

Eva board sheets are transforming the packaging landscape with their remarkable durability and versatility, making them a top choice for modern packaging solutions. One of the most innovative applications lies in their usage for custom-designed boxes that require strength without compromising on weight. These sheets offer an impressive 30 percent increase in durability compared to traditional materials, allowing manufacturers to create lightweight yet robust packaging that protects products—and reduces shipping costs due to lower weight.

Eva board sheets are transforming the packaging landscape with their remarkable durability and versatility, making them a top choice for modern packaging solutions. One of the most innovative applications lies in their usage for custom-designed boxes that require strength without compromising on weight. These sheets offer an impressive 30 percent increase in durability compared to traditional materials, allowing manufacturers to create lightweight yet robust packaging that protects products—and reduces shipping costs due to lower weight.

When it comes to innovative applications, eva board sheets are not just limited to boxes. They are increasingly being used for product displays, reusable bags, and even protective inserts that ensure safe transportation of delicate items. This adaptability allows businesses to tailor their packaging solutions to unique product requirements, enhancing the unboxing experience while promoting sustainability.

Tips: Consider incorporating eva board sheets into your packaging designs to improve product safety and reduce material costs. Additionally, explore creative shapes and sizes that take advantage of the sheets' flexibility, allowing for a more personalized touch that stands out on the shelves. Lastly, stay ahead of sustainability trends by opting for eco-friendly printing techniques on eva board sheets to appeal to environmentally conscious consumers.

The introduction of Eva board sheets is transforming packaging processes across various industries, thanks to their 30 percent increased durability compared to traditional materials. To fully harness the advantages of Eva board sheets, it is essential to optimize packaging methods. One key tip is to conduct thorough testing to identify the right dimensions and formats that maximize material efficiency while minimizing waste. This ensures that the packaging not only provides adequate protection but also aligns with sustainable practices.

Additionally, consider integrating advanced technologies, such as automated cutting and forming machines, which can significantly enhance the precision and speed of the packaging process. By automating repetitive tasks, businesses can reduce labor costs and improve the overall workflow. Furthermore, training staff on best practices for handling and assembling Eva board sheets will ensure that the packaging solutions are utilized to their fullest potential, ultimately leading to superior product protection and customer satisfaction.

| Packaging Material | Durability Increase (%) | Weight (g/m²) | Environmental Impact | Cost Efficiency (%) |

|---|---|---|---|---|

| Eva Board Sheets | 30 | 350 | Low | 20 |

| Corrugated Cardboard | 10 | 400 | Medium | 15 |

| Plastic Sheets | 5 | 500 | High | 10 |

| Pulp Board | 15 | 300 | Medium | 12 |

| Foam Board | 20 | 450 | High | 18 |

The packaging industry is currently experiencing a significant transformation, largely driven by advances in EVA board technology. According to a report by Smithers Pira, the global packaging market is expected to reach $1 trillion by 2027, with an increasing demand for sustainable and durable packaging solutions. EVA board sheets, with their remarkable 30 percent increase in durability compared to traditional materials, are at the forefront of this shift. This enhanced resilience not only reduces the likelihood of product damage during transit but also minimizes waste, aligning with the industry's growing commitment to sustainability.

Moreover, the versatility of EVA board technology allows for innovative applications across various sectors, including food, pharmaceuticals, and electronics. A study from Grand View Research indicates that the demand for sustainable packaging solutions is projected to grow at a CAGR of 5.1% from 2021 to 2028. As businesses seek to improve their environmental footprint, EVA boards offer an attractive alternative due to their recyclability and reduced energy consumption during production. Ultimately, as trends shift towards enhanced durability and sustainability, EVA board technology is poised to revolutionize the packaging landscape over the coming years.