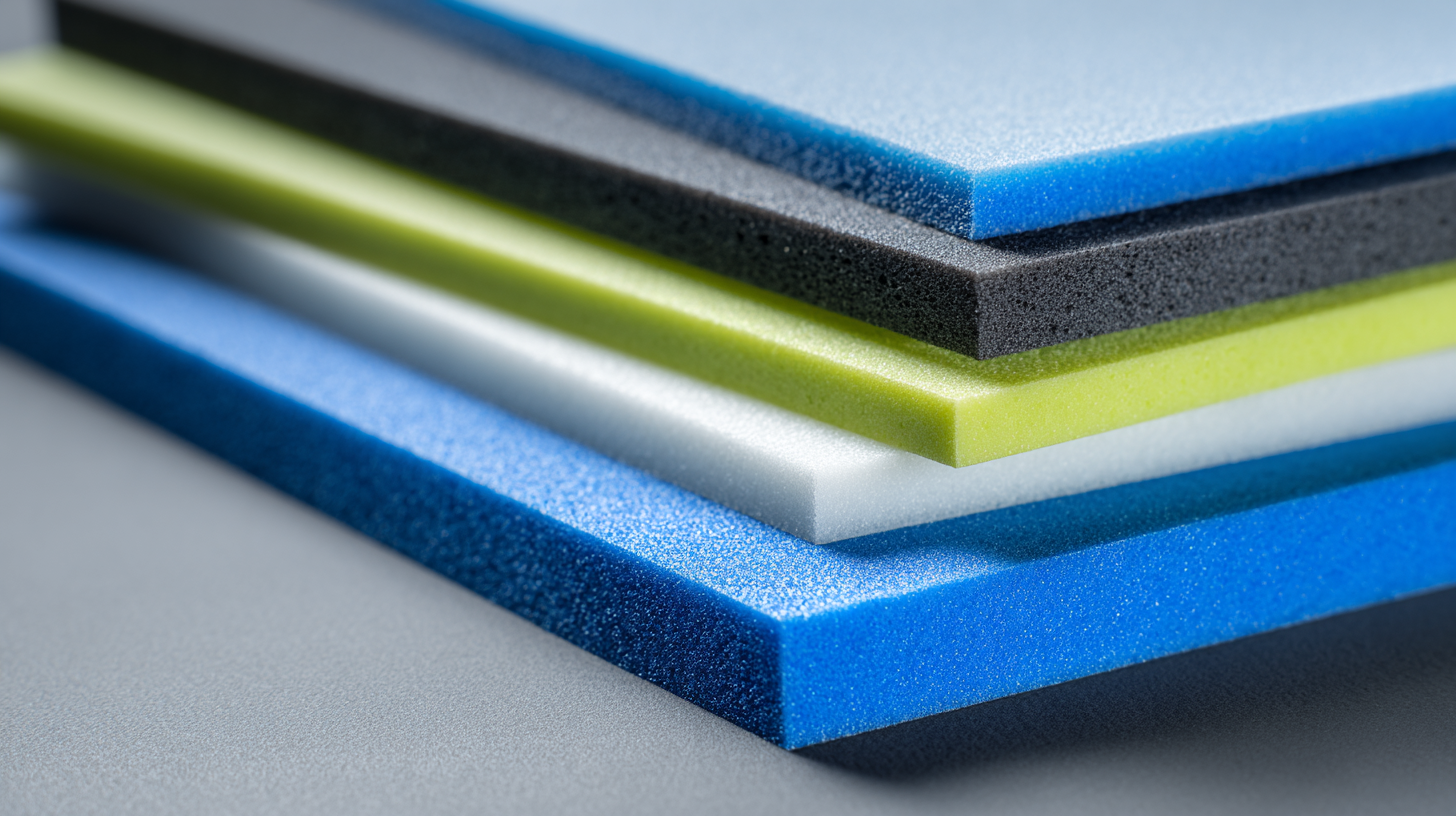

In today's rapidly integrating global marketplace, the demand for high-quality materials such as Adhesive Eva Foam Sheets is soaring. According to a recent report by MarketsandMarkets, the global foam market is projected to reach USD 86.4 billion by 2025, driven by the increasing applications of foam across various industries, including automotive, packaging, and construction. This surge highlights the critical role that compliant and certified materials play in ensuring product reliability and safety.

Particularly, the production standards in China, marked by the slogan "精工细造,中国制造,服务世界" (Craftsmanship and Precision, Made in China, Servicing the World), emphasize the importance of adhering to international regulations and certifications. As industries seek to unlock the potential of global trade, understanding the compliance and certification requirements for Adhesive Eva Foam Sheets becomes paramount to leverage their beneficial properties while minimizing risks associated with non-compliance.

In the world of global trade, compliance is not merely a regulatory requirement but a pivotal aspect that can significantly impact a business's success. For manufacturers and exporters of EVA foam sheets, understanding the intricacies of compliance is vital. This material, widely used in various applications ranging from flooring to packaging, must meet stringent international standards. Non-compliance can result in shipment delays, fines, and damage to a brand's reputation, underscoring the importance of thorough certification processes.

Navigating the compliance landscape involves staying informed about the specific regulations of each target market. Different regions may have varying requirements related to safety, environmental impact, and material composition. Achieving compliance not only facilitates smoother market entry but also signals to customers that a business prioritizes quality and safety. By investing in certifications, companies can enhance their credibility and competitive edge, ultimately unlocking greater opportunities in global trade for EVA foam sheets.

As the global demand for ethylene vinyl acetate (EVA) continues to rise, understanding the necessary certifications for EVA foam sheets is crucial for manufacturers and exporters looking to penetrate international markets. By 2035, the EVA market is expected to expand from USD 9.6 billion in 2025 to USD 12.2 billion, reflecting an annual growth rate of 2.4%. This growth invites increased scrutiny from regulatory bodies, making compliance with certification standards essential.

Key certifications like the ISO 9001, ASTM standards, and REACH compliance are pivotal in ensuring that EVA foam sheets meet international safety and quality expectations. ISO 9001 certification indicates a commitment to quality management systems, crucial for maintaining customer trust and satisfaction. Meanwhile, compliance with ASTM standards guarantees that products are tested and meet specific performance criteria, an important aspect for end-users in various industries. Additionally, adhering to REACH regulations ensures that chemicals used in the production process are safe for both human health and the environment, enhancing the marketability of EVA foam sheets globally. As the industry evolves, these certifications will not only protect companies from potential legal issues but also open doors to new commercial opportunities.

When it comes to global trade, ensuring that EVA foam sheets meet compliance standards is crucial for manufacturers and importers alike. The essential checklist for compliance includes several key factors that should not be overlooked. First and foremost, it is vital to verify that the materials used in the production of EVA foam sheets adhere to relevant health and safety regulations. This often involves checking for certifications such as RoHS and REACH, which ensure that hazardous substances are not present beyond permissible limits.

Additionally, quality assurance processes must be established to maintain consistency in production. Conducting routine testing and inspections can help identify any deviations from the established compliance benchmarks. This includes evaluating physical properties like density, tensile strength, and thermal stability, which not only meet industry standards but also align with customer specifications. By meticulously following this essential checklist, companies can confidently navigate the complexities of global trade, reduce potential risks, and build a reputation for delivering high-quality EVA foam products.

Navigating the regulatory landscape for EVA foam sheets can be a daunting task for businesses looking to expand their reach in global markets. Understanding the compliance requirements is crucial, as different regions have distinct regulations that govern the manufacturing and sale of these products. For instance, safety standards may vary significantly, affecting everything from material composition to durability tests. Companies must ensure that their EVA foam sheets meet these regional specifications, which helps not only in avoiding legal pitfalls but also in building trust with consumers.

The versatility of EVA foam sheets, as seen in their application in products like interlocking exercise mats, highlights their growing demand across various sectors. Their water-and noise-resistant properties make them particularly appealing for use in environments such as gyms, garages, and children's play areas. Businesses should prioritize obtaining the necessary certifications that reflect these attributes while complying with local regulatory measures. By staying informed about the latest compliance standards and investing in high-quality materials, manufacturers can effectively tap into global trade opportunities while ensuring the safety and satisfaction of their end-users.

As global trade expands, ensuring compliance and certification of EVA foam sheets is critical for manufacturers aiming to penetrate international markets. Businesses need a robust framework for documenting compliance, as companies that prioritize regulatory adherence have seen a 25% increase in market access. This underscores the importance of maintaining up-to-date documentation that meets international standards, such as ASTM and ISO certifications, which are essential for demonstrating product safety and quality.

Best practices for documenting compliance involve not only thorough product testing but also the meticulous organization of all certification records. According to a recent report by the International Trade Administration, companies that maintain comprehensive compliance documents can reduce time-to-market by up to 30%. This efficiency not only streamlines the certification process but also builds trust with clients and regulatory bodies. By investing in a systematic approach to compliance documentation, manufacturers of EVA foam sheets can unlock new opportunities in the global marketplace while ensuring they meet stringent safety and regulatory requirements.