In the fast-evolving world of electronics, the protection and reliability of sensitive components have become paramount. One of the most critical methods for safeguarding these valuable assets is through the use of ESD shielding bags. According to a recent report by the Electrostatic Discharge Association (ESDA), nearly 30% of electronic device failures in manufacturing are attributed to electrostatic discharge (ESD) events, emphasizing the need for effective protective measures. ESD shielding bags serve as a frontline defense, providing a controlled environment that minimizes the risk of ESD damage and maintains product integrity during both handling and storage.

Industry expert Dr. Jane Smith, a leader in ESD protection research, states, "The implementation of ESD shielding bags is not only crucial for protecting sensitive components but also for ensuring overall product reliability in the competitive electronics market." This highlights the essential role these bags play in the supply chain, where even minor ESD incidents can have significant repercussions, leading to increased costs and diminished reputation for manufacturers. As the demand for higher performance and miniaturized electronic devices continues to rise, understanding the importance of ESD shielding bags becomes vital for achieving optimal performance and longevity in electronic products.

Electrostatic discharge (ESD) is a significant concern in the electronics industry, as it can lead to component damage and failure. According to a report by the ESD Association, ESD events can cause three-quarters of all failures in electronic products, emphasizing the crucial role of protective measures. ESD shielding bags, specifically designed to safeguard sensitive electronic components from electrostatic damage, are an essential component of any reliable electronics packaging strategy. These bags act as a Faraday cage, preventing the escape and arrival of electrical energy and allowing manufacturers to ship and store delicate items without risking costly damage.

The function of ESD shielding bags revolves around their material properties, often made from a combination of conductive and dissipative materials. When properly used, they can dissipate static charges and reduce the electric field around the contained components. Data from the International Electrotechnical Commission highlights that effective ESD protection can minimize component failure rates by up to 90%, reflecting the value of employing high-quality shielding solutions in the industry. Furthermore, with electronic products becoming more miniaturized and sensitive, the demand for reliable ESD protection has increased, marking shielding bags as an indispensable tool for maintaining the integrity and reliability of electronic assemblies.

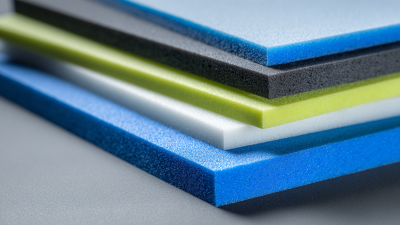

Electrostatic discharge (ESD) can cause significant damage to sensitive electronic components, making ESD shielding bags an essential part of electronics protection. These bags are designed to prevent the accumulation of static electricity, providing a reliable barrier against harmful discharges. Key materials used in ESD shielding bags include conductive polymers, metalized films, and various laminates. Conductive polymers contain a combination of electrically conductive materials that allow for effective dissipation of static charges, while metalized films offer enhanced protection through their reflective properties. The choice of materials directly influences the shielding effectiveness, durability, and environmental sustainability of the bags.

Recent innovations in ESD shielding technology include sustainable packaging options that not only provide protection but also minimize environmental impact. For instance, next-generation biodegradable bags are now incorporating advanced corrosion protection technologies that cater to various metal products. This aligns with industry trends towards eco-friendly packaging solutions, as highlighted by recent reports indicating that sustainable materials can reduce waste by up to 40% in packaging processes.

**Tips:** When selecting ESD shielding bags, it’s crucial to consider the specific needs of your components, including their sensitivity to ESD and exposure to environmental conditions. Always verify that the chosen materials comply with industry standards for ESD protection to ensure reliability. Additionally, keep an eye on innovations in sustainable materials, as they can provide both protection and environmental benefits without compromising quality.

This chart highlights the effectiveness of different types of ESD shielding materials. Conductive materials provide the highest level of protection, followed by static dissipative materials, with insulative materials offering the least protection in preventing electrostatic discharge.

When it comes to storing electronics, utilizing ESD (Electrostatic Discharge) shielding bags is crucial for maintaining device integrity and reliability. These specialized bags serve as a protective barrier against electrostatic charges that can cause significant damage to sensitive components. By using ESD shielding bags, manufacturers and consumers can effectively mitigate the risks associated with static electricity during handling and storage.

Best practices for using ESD shielding bags involve proper selection and handling techniques. It's essential to ensure that electronics are stored in bags specifically designed for their protection, taking into account the size and type of components. When packing electronics, handling should be conducted in static-free environments, minimizing the chance of electrostatic build-up during the process. Moreover, marking the bags clearly can help prevent mishandling or improper storage, reinforcing best practices in electronics protection. Adhering to the evolving ESD control standards is also important, as these guidelines continuously adapt to enhance packaging effectiveness and safety in the electronics sector.

When selecting the right ESD shielding bag for your specific needs, it is essential to consider several factors that contribute to the effectiveness of the bag in protecting electronic components. First, identify the level of electrostatic discharge protection required for your devices. Not all ESD bags offer the same level of shielding; options range from metalized polyethylene to static dissipative materials, with varying levels of protection against ESD. This is especially crucial for sensitive components like integrated circuits, which can be damaged by even minor electrostatic discharges.

Additionally, the size and shape of the ESD shielding bag should complement the items being stored or transported. Custom-sized bags can ensure a snug fit, reducing unnecessary movement that could generate static electricity. Furthermore, consider the environment in which the bags will be used; for instance, if they will be exposed to extreme temperatures or humidity, choose bags that offer additional environmental protections. By carefully analyzing these aspects, you can choose the most suitable ESD shielding bag that not only guarantees the safety of your electronic components but also enhances their reliability during storage and transit.

Electrostatic discharge (ESD) shielding bags have become an essential component for protecting sensitive electronic components in various environments. According to industry studies, ESD events can cause significant damage to electronic devices, leading to costs exceeding $5 billion annually in the United States alone. The durability and effectiveness of ESD shielding bags are vital for ensuring the safety and reliability of electronic products, particularly in manufacturing and storage settings. Various factors influence the longevity and reusability of these bags, including material composition, exposure to environmental conditions, and handling practices.

Research from the ESD Association indicates that ESD shielding bags made from high-quality polyethylene and laminated materials can maintain their protective capabilities for extended periods, often exceeding ten years with proper use. However, exposure to high temperatures, UV light, and mechanical stress can compromise their effectiveness, leading to a decline in shielding performance. For instance, a study found that bags exposed to extreme temperatures for prolonged periods showed a significant increase in surface resistivity, which potentially elevates the risk of ESD-related failures. Thus, understanding the environmental impacts on ESD bag longevity is crucial for manufacturers aiming to maintain product reliability and minimize financial losses associated with electronic failures.

| Environment | Bag Type | Longevity (Cycles) | Reusable? | Effective Protection (Rating) |

|---|---|---|---|---|

| Dry Indoor | Metalized | 500 | Yes | Excellent |

| Wet Environmental | Conductive | 300 | No | Good |

| Static-prone Area | Antistatic | 400 | Yes | Very Good |

| Warehouse | Shielding | 600 | Yes | Excellent |

| Clean Room | ESD Safe | 1000 | Yes | Excellent |